Engineering at OES

Powering Progress Through Engineering Excellence

Engineering Excellence

At Orient Energy Systems (OES), we combine technical expertise with practical innovation to deliver world-class engineering services in Pakistan. Our multidisciplinary teams — spanning Electrical/Electronic, Mechanical and Civil Engineering which are adequately supported by a dedicated CAD design unit that enables precision planning and seamless project execution. From design and development to commissioning and performance validation, our engineering expertise ensures every system meets global standards for reliability, efficiency and safety.

Why Choose OES Engineering

Engineers

A team of 200+ engineers trusted by industries nationwide for reliability and precision.

Turnkey Solutions

End-to-End Support: From initial design to post-commissioning maintenance.

Engineering Tech Tools

CAD design, drafting, and structural analysis using engineering technology tools such PRIMEVERA, CADWORKS, AUTOCAD

Multidisciplinary Projects

Gas, diesel or hybrid power plants, OES transforms complex energy requirements into practical, high-performing, and sustainable engineering outcomes

Project Engineering

At Orient Energy Systems (OES), our Project Engineering division brings together a multidisciplinary team of Electrical, Mechanical, and specialized Computer-Aided Design (CAD) department. This integrated expertise enables us to deliver end-to-end engineering solutions across a wide range of applications, including gas and diesel power generation, HVAC, RO plants, solar systems, and air compression projects.

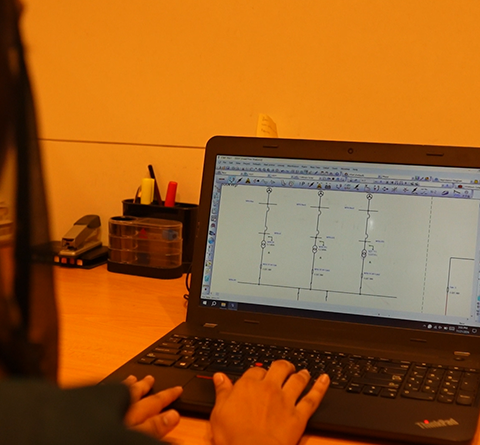

Electrical & Electronic Engineering Team

Our Electrical and Electronic Engineering division is responsible for the design, integration, and control of power systems across all project scales — including diesel and gas gensets, switchgear systems, and plant automation.

Core capabilities include:

- Power distribution design and load flow analysis

- Control system and PLC panel design

- Generator synchronization, protection, and automation

- SCADA and remote monitoring integration

- Cable routing and single-line diagram development

Tools & Software Used:

- ETAP

- AutoCAD Electrical

- EPLAN

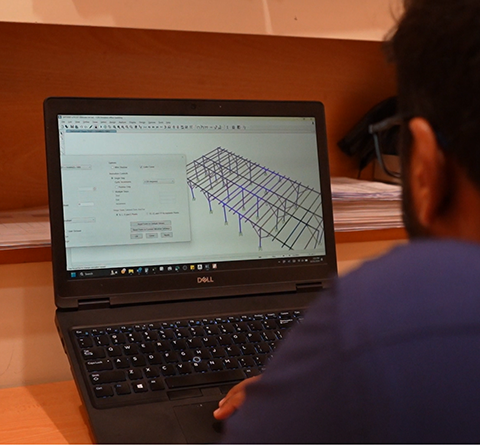

Mechanical Engineering Team

The Mechanical Engineering team ensures the mechanical integrity, performance, and efficiency of all power generation systems. They design and validate all aspects of engine, cooling, and exhaust systems while optimizing space utilization and performance.

Core capabilities include:

- Mechanical system design and layout planning

- Cooling, ventilation, and exhaust system engineering

- Skid and baseframe design

- 3D modeling of mechanical assemblies

- Vibration and stress analysis for rotating equipment

Tools & Software Used:

- Autodesk Inventor

- ANSYS

- AutoCAD Mechanical

- STAAD.Pro

- AutoCAD Civil 3D

- SAP2000

CAD Design & Drafting Team

The CAD Design Department plays a vital role in supporting all engineering functions by producing high-precision technical drawings and 3D models for project visualization and fabrication.

Core capabilities include:

- 2D/3D drafting and as-built documentation

- Clash detection and layout coordination

- Equipment layout drawings and P&IDs

- Virtual walkthroughs and 3D visualization for client review

- Vibration and stress analysis for rotating equipment

Tools & Software Used:

- AutoCAD

- Autodesk Plant 3D

Applications Across Industries

Industrial and captive power

Cummins EBU engines provide reliable power for manufacturing, oil & gas, mining and other heavy-duty operations.

Versatile fuels and environments

The broad engine platform supports varying fuel-types and operational conditions, making it suitable for Pakistan’s diverse energy demands.

Reduced risk & downtime

With the strength of the Cummins EBU technology and OES’s local service capability, customers can expect high availability and simplified maintenance.